Lunghwa’s Practical Abilities Surpasses National Universities in Assisting Manufacturers in Successfully Developing Monitoring Antenna Sensors for Blood Vessels

A domestic foundation commissioned a national university to simulate and develop a passive antenna sensor for AI-powered wireless monitoring of human blood vessels, but ultimately, it was unsuccessful. Later, the commissioning unit learned that Lunghwa University of Science and Technology had the relevant equipment and practical technical capabilities. In February 2024, they approached Lunghwa for cooperation. Under the guidance of Professor Yih-Chien Chen, Vice President of Lunghwa University of Science and Technology, two students successfully completed the prototype of the monitoring antenna sensor for blood vessels in just two months. It has recently been delivered to the manufacturer for further animal experiments, hoping to contribute more to the AI medical industry in Taiwan.

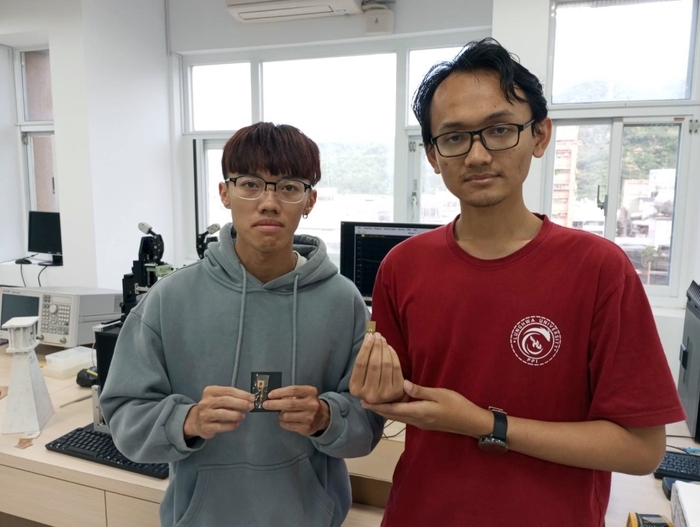

Responsible for the research and development of the project was Dyan Eko Wahyu, a master’s student from Indonesia in the Department of Electrical Engineering, and local student Zhujun Xu taking the PBL IoT Technology Leadership Program. They overcame numerous difficulties and challenges, ultimately successfully designing and developing the prototype of the antenna sensor, demonstrating that the practical abilities of Lunghwa students have surpassed those of national universities.

Professor Yih-Chien Chen, the supervisor of Dyan and Zhujun Xu, stated that upon receiving the project task, the two students utilized their spare time to read the relevant information provided by the commissioning unit and analyzed many domestic and international journal articles. They immediately immersed themselves in the laboratory for the first phase: simulation, fabrication, and dynamic verification of the Cu/Polyimide base material. Upon successful completion, they proceeded to the second phase: simulation and fabrication of Mg foil/biocompatible thin film materials and dynamic verification. During the simulation, the reader outside the body was also included as a condition to produce the corresponding reader antenna.

Dyan said that based on journal papers, they concluded that they began designing and developing the sensor using HFSS software and simulated the results of the antenna and sensor. Once the simulation results were satisfactory, they proceeded to the implementation and measurement phase. For implementation, they used a laser engraving machine to engrave the antenna and sensor prototype, while for measurement, they used a KEYSIGHT vector network analyzer. The entire process, from design to manufacturing and measurement, was carried out using the established hardware and software at Lunghwa without needing external assistance.

Zhujun Xu said that the most challenging part was the process of bonding the copper foil to the PI film base material because the copper foil needed to be engraved first, requiring multiple trials and adjustments of the parameters of the laser engraving machine to ensure that the necessary parts were accurately produced. After completion, the copper foil had to be bonded to the PI film neatly and tightly; otherwise, there would be significant deviations in the measurement results. This stage tested patience considerably, and it was fortunate that they eventually completed the task successfully.

Vice President Yih-Chien Chen pointed out that this project is one of the many successful cases of industry-academia collaboration at the university, mainly because Lunghwa University of Science and Technology has three production line bases funded by the Ministry of Education for practice and related laboratories, which integrate the entire process chain of electronic product development, circuit design, layout, product production, component assembly, product testing, electrical testing, and product verification. It can provide manufacturers with integrated services from design, development, and manufacturing to testing.

Vice President Chen emphasized that Lunghwa University of Science and Technology is committed to becoming Asia’s best talent cultivation base in electronics. The faculty and student teams will continue to understand industry needs through industry-academia cooperation, enabling practical research to link with the industry chain, helping to reduce the gap between theory and practice, and simultaneously cultivating high-quality talents for the industry.

Secretariat Office, the Lunghwa University of Science and Technology

Contact: LI,CHIANG-SHENG

Office Phone: 82093211#2012

E-mail: lcs222@mail.lhu.edu.tw